The simplicity of golf is its biggest con job. You hit a ball with a membership. Easy sufficient till you notice that seemingly harmless little white orb holds extra engineering secrets and techniques than NASA’s backup servers.

Look beneath the dimpled exterior and also you’ll discover a world the place obsessive perfectionists wage each day battles towards physics. These fundamental golf equipment and balls conceal designs that marry old-world craftsmanship with space-age supplies—form of reminds you of that scene in “The Status” the place the straightforward magic trick required years of innovation backstage.

Understanding the manufacturing behind your gear gained’t simply fulfill curiosity. It’d really prevent three strokes. Subsequent time you cranium a wedge throughout the inexperienced, bear in mind: it’s not the arrow, it’s the archer. Often.

Disclaimer: Some photographs used for commentary and academic functions underneath truthful use. All rights stay with their respective house owners.

Wound Golf Balls

There’s one thing virtually sacred about wound golf balls in an period when every part retains getting “optimized” to demise. They’re golf’s vinyl information in a streaming world—much less handy however one way or the other extra genuine.

Professional retailers don’t inventory many anymore, however purists nonetheless hunt them down like craft beer lovers looking for a restricted launch IPA. These beauties get crafted by means of a course of that may make a Swiss watchmaker nod: rubber thread wrapped with monk-like endurance round a middle core. Whereas at this time’s premium multilayer urethane balls have narrowed the hole, wound balls keep a faithful following. The development creates a softness that lets expert gamers form photographs like sculptors. For golfers who care extra about artistry than bombing it previous the 300-yard marker, these wound balls provide a definite taking part in expertise that trendy know-how nonetheless tries to emulate.

Two-Piece Golf Balls

Let’s face info—most of us aren’t precisely channeling Tiger circa 2000 on the market. We’re extra “Tiger King” than Tiger Woods. That’s why nearly all of us mere mortals go for two-piece golf balls.

The development couldn’t be extra simple: stable rubber core wrapped in a troublesome outer shell extra dimpled than an adolescent with unhealthy zits. Ball makers preserve this design fundamental for a motive—most distance whereas protecting prices low sufficient that you just gained’t want remedy after dumping a sleeve into the lake. At round $20 per dozen, shedding them hurts about as a lot as a paper reduce.

That more durable exterior really helps your wayward swing by decreasing these embarrassing banana slices. It’s the golf equal of bowling with bumpers, and weekend warriors in all places silently thank the engineers whereas pretending it was pure talent that saved that drive in play.

Golf Ball Core Formation

Subsequent time you crush a drive (or extra seemingly prime it 40 yards), think about the Willy Wonka-esque manufacturing unit the place your ball’s coronary heart got here to life. The core formation begins in industrial amenities the place rubber compounds rework by means of a course of that makes sourdough bread preparation look easy.

The bouncy rubber will get combined with chemical components that producers guard extra intently than Augusta Nationwide guards its membership record. This concoction heats till it turns into a sticky batter earlier than going by means of precision extruders. Out pop these weird marshmallow-shaped slugs bearing zero resemblance to golf tools. Every producer has their very own closely-guarded specs for temperature and length throughout the baking course of. These proprietary settings rework mushy rubber into one thing with the precise properties wanted to launch off your driver face at ridiculous speeds.

Golf Ball Shell Formation

These dimples aren’t simply cute facial options—they’re aerodynamic marvels that make the distinction between your ball flying like an eagle or a wounded duck. Creating them requires engineering that may make NASA nod in appreciation.

Producers warmth thermoplastic materials till it flows like maple syrup, then inject it underneath stress into specialised molds. Every cavity comprises the adverse impression of the ball’s floor, full with these scientifically calculated dimple patterns. The machines spit out 4 dozen completed shells each minute—quicker than most hackers lose balls in a spherical at Sawgrass. As soon as cooled, these shells await their marriage to the cores, reworking into these pristine white spheres destined for greatness—or extra seemingly, the underside of the pond on the par-3 twelfth.

Golf Ball Ending and High quality Management

The ultimate levels of golf ball manufacturing may be probably the most spectacular half, or as they are saying in Caddyshack, “the Cinderella story” the place the ugly duckling transforms right into a tournament-ready magnificence.

After core and shell come collectively, automated milling machines trim extra plastic with micron-level accuracy. High quality inspectors confirm excellent spherical form at a number of checkpoints. Any ball falling brief will get yanked quicker than a putt that missed the break. Robotic arms stamp on logos and numbers with sci-fi precision, immediately UV-dried to stop smudging. A protecting polyurethane coating provides that particular sheen whereas enhancing sturdiness. The freshly coated balls then spend precisely 5 minutes drying at 150°F earlier than packaging. All this know-how, precision, and expense simply so you’ll be able to three-putt from 15 toes.

Picket Golf Membership Head Shaping

When golf nerds get misty-eyed speaking about persimmon, they’re not discussing fruit salad substances. The creation of picket membership heads marries Outdated World craftsmanship with delicate artistry in a means that makes trendy manufacturing look soulless.

All the things begins with premium persimmon wooden choice—chosen for density and grain patterns. Craftspeople quarter-saw these logs with cautious precision to make sure grain runs precisely proper for optimum structural integrity. Specialised duplicating machines observe grasp mannequin contours, carving each bit to exacting specs. A chopping software carves a exact slot throughout the long run putting face to deal with reinforcing plastic. Maybe most spectacular is the router work creating that elegant hourglass-shaped cavity beneath for the steel sole plate. The sheer labor depth explains why collectors deal with these golf equipment with reverence sometimes reserved for non secular artifacts and uncommon bourbon.

Picket Golf Membership Head Weighting and Ending

What separates a garden-variety picket membership from the type Ben Hogan would really deign to hit? It’s all about weight steadiness—and producers obsess over it with the depth of a placing stroke over a 4-footer to win the membership championship.

The tolerances would make a NASA engineer nervous. Every membership head should fall inside 3 measly grams of goal weight. Craftspeople obtain this by strategically positioning lead pellets all through the pinnacle. A exactly fitted chrome steel sole plate will get put in on the underside, defending the wooden whereas including simply sufficient further heft. Look intently at any high quality persimmon driver and also you’ll discover fantastic grooves on the face—every line scored by technicians utilizing what quantities to a jeweler’s noticed. After form and weight perfection comes the staining course of, adopted by 5 separate layers of protecting polyurethane, creating that attractive shiny end worthy of each golf luggage and museum shows.

Picket Golf Membership Meeting

The wedding of shaft to go in picket golf equipment includes extra precision than a coronary heart surgeon wants on a Monday morning. It’s this meeting course of that separates heirlooms from kindling.

First comes securing a steel sleeve contained in the neck utilizing specialised adhesives. The sleeve creates that vital connection level for the shaft, which should align with mathematical precision. Getting the shaft alignment even 1 diploma off is the tools equal of lacking the green by 30 yards. As soon as correct alignment’s achieved, craftspeople add exactly measured quantities of pulverized lead for weight fine-tuning. When full, a correct picket membership represents concord between custom and innovation that delivers each basic magnificence and purposeful excellence.

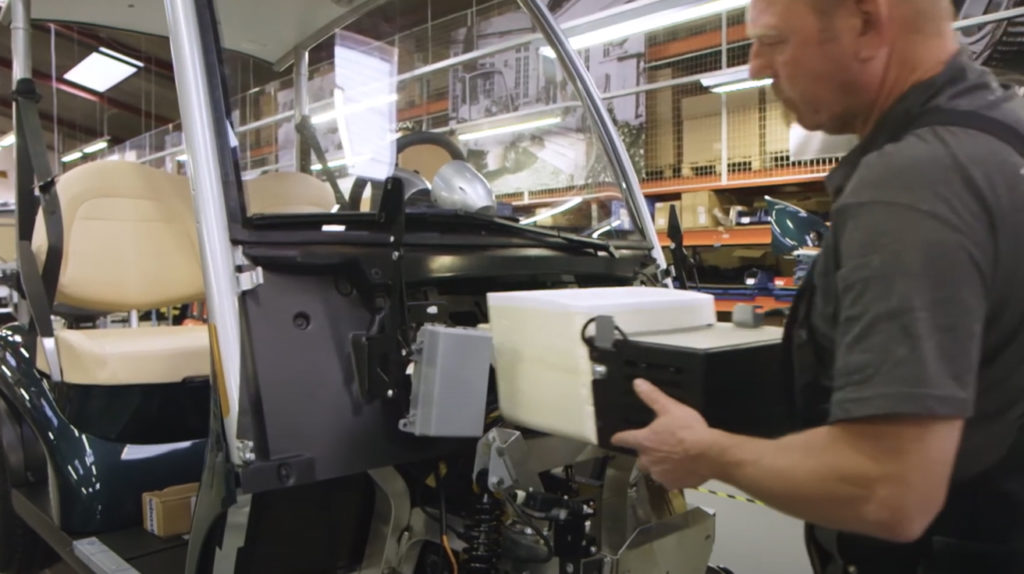

Motorized Golf Cart Body and Physique Meeting

Golf carts have advanced from glorified wheelbarrows to one thing nearer to luxurious cars. At present’s fashions have extra engineering DNA from Tesla than from these rickety pull carts your grandfather complained about.

All the things begins with the body—producers have principally switched to aluminum I-beams that convey outstanding structural power with out pointless weight. Sensible materials selection improves each effectivity and dealing with, turning potential cart paths into miniature Autobahns. The seating deserves particular point out: marine-grade plywood platforms (chosen for climate resistance) coated with vinyl over supportive foam padding. These ergonomic thrones make an enormous distinction throughout five-hour rounds when your buddy retains in search of balls in locations Lewis and Clark wouldn’t discover. Energy comes from surprisingly subtle 48-volt electrical motors that run cleaner and quieter than a well-oiled putter stroke. Past simply shifting gamers round, these eco-friendly powerplants align completely with golf’s rising environmental consciousness—as a result of nothing says “appreciation of nature” fairly like driving by means of it slightly than strolling. Impression-resistant plastic physique panels defend the costly bits from inevitable encounters with tree trunks, coolers, and that one man who retains forgetting to set the parking brake. The end result? An ideal steadiness of consolation and sturdiness that makes trendy cart rides virtually as gratifying as making a birdie. Nearly.

Motorized Golf Cart Powertrain and Part Set up

Don’t be fooled by their informal look—trendy golf carts pack sufficient engineering complexity underneath their plastic skins to make a mechanical engineer spill his Arnold Palmer.

The center of any cart is its electrical powertrain, a compact marvel that may impress Elon Musk if he ever took a break from ruining Twitter to play golf. Meeting begins with technicians positioning the axle meeting instantly atop the differential—a setup maximizing energy supply whereas minimizing power waste. The 48-volt electrical motor will get bolted to mounting factors utilizing fasteners torqued to actual specs. This precision issues—any extra vibration would make the cart really feel as refined as a $2 putter from a storage sale. Energy transfers from motor to wheels by means of an built-in transaxle, basically a simplified transmission optimized for the stop-start nature in fact navigation. The batteries sometimes occupy the rear compartment—not only for comfort however to steadiness weight distribution in a means that stops the cart from doing wheelies when your buddy stomps the accelerator after three beers. 4 thick wires join these batteries to the motor controller, forming {the electrical} lifeline of the entire operation. Governing every part is an digital management module—the cart’s silicon mind—that manages acceleration, pace, and energy output with better care than most of us handle our precise golf swings.

Motorized Golf Cart High quality Management and Ending

You would possibly assume golf cart manufacturing includes about as a lot high quality management as a child’s lemonade stand. You’d be useless incorrect. These amenities run tighter ships than the Secret Service defending a presidential foursome.

Throughout meeting, subtle laptop methods monitor torque values at quite a few connection factors. Every fastener should hit exact specs—too free and issues rattle aside quicker than a weekend hacker’s swing; too tight and elements crack underneath stress. Security rules mandate carts can’t exceed 15 mph—a restriction constructed into management methods. The seating set up receives particular scrutiny: entrance and rear benches should match with excellent alignment. As soon as assembled, specialised elevate methods carry every cart by means of closing inspection the place technicians confirm every part from flip indicators to brakes. Solely after clearing these hurdles does a cart obtain closing blessing to move golfers and their more and more ridiculous array of equipment across the course.

Stainless Metal Golf Membership Head Casting

The delivery of a contemporary chrome steel membership head includes processes extra akin to medieval alchemy than manufacturing. It’s the tools model of “Sport of Thrones”—fireplace, steel, and occasional shouting.

All the things begins with creating excellent wax duplicates of the membership design. Technicians inject heated wax into molds detailed sufficient to seize fingerprints. These wax fashions get coated with specialised ceramic materials, every layer strengthened with silica sand. In the meantime, employees warmth chrome steel bars to 3000°F whereas ceramic molds attain 1800°F. When each hit optimum temperatures, employees pour molten steel into the heated molds, inflicting the wax to vaporize fully (therefore “misplaced wax casting”). After cooling for five hours, employees break free the ceramic shells, revealing newly-formed membership heads. The method combines industrial precision with dramatic aptitude that may make for riveting tv if the Historical past Channel ever runs out of pawn store exhibits. ceramic molds themselves bear preheating to about 1800°F.

When every part reaches the correct temperature, foundry employees rigorously pour the molten metal into the heated ceramic molds. The acute warmth causes the wax inside to vaporize fully (a method appropriately known as “misplaced wax casting”), leaving an ideal cavity for the steel to fill.

After cooling for about 5 hours, the now-solid steel membership heads are prepared for extraction. Employees rigorously break free the ceramic shell utilizing specialised hammers, revealing the newly-formed membership heads inside. It’s a dramatic second – like cracking open a geode to disclose the treasure inside.

Stainless Metal Golf Membership Ending and Meeting

Uncooked solid membership heads resemble prehistoric instruments greater than precision sporting tools. The transformation from caveman relic to professional store magnificence requires extra steps than Augusta Nationwide par-5.

First comes sandblasting to create particular floor textures that have an effect on efficiency. Completely different zones want completely different finishes: the face requires one texture for correct ball contact, whereas the only calls for one other for turf interplay. Subsequent, technicians connect these shiny badges that present vital mannequin data. Membership identification continues with automotive-grade paint marking every exact loft angle. Earlier than the shaft meets head, employees apply specialised epoxy to connection factors—engineered particularly to resist the violent forces created by weekend warriors attempting to kill the ball. Meeting culminates with pneumatic hammers driving shafts into place. The end result? A membership delivering constant really feel and efficiency—a minimum of till you blame it on your slice into the chief car parking zone.

Golf Membership Shaft and Grip Set up

That a part of the membership you really contact might sound fundamental as toast, however grip set up includes engineering subtle sufficient to make Silicon Valley nerds sweat.

Earlier than something occurs, technicians reduce every shaft to specific size. The suitable size will depend on participant peak, arm size, and swing traits—even a quarter-inch distinction can rework a possible birdie right into a catastrophe. Employees wrap the higher 10 inches with specialised double-sided tape engineered particularly for this objective. Fashionable grips function superior supplies balancing tackiness and sturdiness. Getting them completely straight issues tremendously, which is why producers more and more make use of laser alignment methods. Subsequent time you blame tools on your flubbed chip, bear in mind: somebody used precise lasers to make sure your grip was put in with the precision of neurosurgery. the higher 10 inches with specialised double-sided tape engineered particularly for this objective—with adhesive properties balanced between fast tack and long-term bonding that may make relationship counselors jealous. Fashionable grips function superior supplies balancing tackiness, shock absorption, and sturdiness. Getting them completely straight issues tremendously—even tiny misalignment could cause delicate swing issues that accumulate quicker than bogeys on a windy day. That’s why producers more and more make use of laser alignment methods guaranteeing excellent positioning. Subsequent time you blame tools on your flubbed chip, bear in mind: somebody used precise lasers to make sure your grip was put in with the precision of neurosurgery, making your excuse weaker than fuel station espresso.

Golf Membership Angle and Weight Adjustment

The times when membership changes occurred by eyeball and really feel disappeared quicker than free vary balls at a public driving vary. At present’s course of resembles a laboratory scene from a sci-fi film.

Fashionable membership becoming employs laptop methods that measure with accuracy that may make Swiss watchmakers slow-clap. Specialised diagnostic tools detects variations in lie and loft angles right down to 0.1 levels—variations invisible to the bare eye however able to sending your ball to neighboring zip codes. After measurement comes adjustment, typically involving delicate hosel bending. Weight adjustment includes positioning an 18-gram weight (really nearer to 17.7 grams to accommodate epoxy mass) with surgical precision. This fanatical consideration to element explains why skilled golf equipment carry out with outstanding consistency. Sadly, all this precision nonetheless can’t repair your over-the-top transfer that sends balls screaming towards the car parking zone.

This course of makes roughly 3,000 completed tees, demonstrating outstanding materials effectivity. The logs first progress by means of an automatic debarking course of. This equipment removes the outer layer and any floor impurities. A specialised slasher noticed then cuts the logs to optimum processing size. These preparatory steps create the uncooked materials basis for manufacturing constant, high-quality tees.

Picket Golf Tee Manufacturing: Log Preparation

Some say legend started with a easy picket tee. White birch is scaled for tee manufacturing. Only one 8-inch log yields many tees. It makes virtually 3,000 tees from one log. The logs undergo a debarking course of. This removes the outer layer and impurities. A slasher shortens the logs. These steps prepared the wooden for tees.

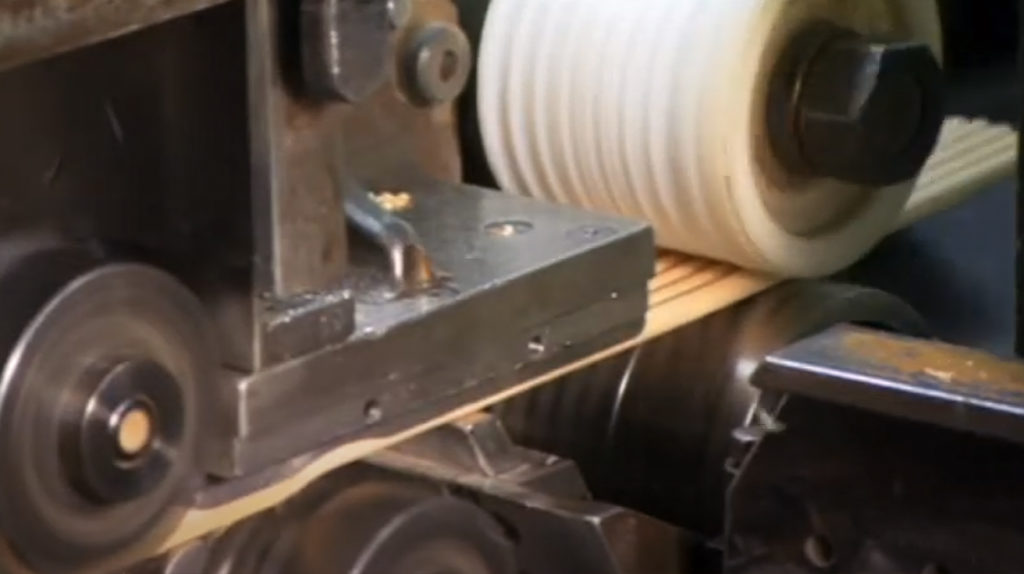

Picket Golf Tee Manufacturing: Dowel Formation

Remodeling uncooked lumber into these completely formed tees includes extra industrial would possibly than most golfers think about whereas absentmindedly jabbing them into the turf.

Industrial-grade saws slice boards into manageable dimensions with the effectivity of a event guidelines official shutting down artistic interpretations of “informal water.” These machines rework 4.5-inch boards into narrower sections measuring roughly 18 inches lengthy. Excessive-speed molding machines grip these rectangular items and quickly spin them towards chopping heads, reshaping them from squared lumber into completely spherical dowels smoother than a tour professional’s placing stroke.

Picket Golf Tee Manufacturing: High quality Management and Shaping

High quality inspectors consider dowels with requirements stricter than Augusta Nationwide’s member choice committee. These eagle-eyed professionals don’t fiddle with mediocrity.

Skilled personnel kind roughly 19,000 dowels hourly, guaranteeing solely excellent specimens proceed the journey. Specialised racks safe these accredited dowels, every holding as much as 8,900 particular person items. A precision lathe then shapes every dowel right into a tough profile quicker than a marshall speeds towards sluggish gamers. The ultimate transformation occurs by means of the “trumpet,” a specialised software that concurrently sculpts and slices every tee to size. The distinctive cup formation develops naturally throughout separation, creating the proper cradle on your ball earlier than you skinny it thirty yards instantly into the group forward.

Picket Golf Tee Manufacturing: Sanding and Sorting

Mass manufacturing of golf tees requires industrial ending tools that may make your native woodworker’s store appear like a toddler’s toy set.

Semi-finished tees tumble inside large sanding drums with the chaotic power of a scramble event after an open bar. This course of smooths each floor, guaranteeing your fingers gained’t catch splinters when nervously fidgeting earlier than making an attempt to drive the inexperienced. Subtle equipment separates excellent tees from these with microscopic flaws. The usual tee emerges measuring exactly 2.5 inches with consistency. Every weighs roughly 0.02 grams—lighter than your probabilities of making that 30-footer for eagle. Large storage totes include these processed treasures in bulk portions. A single container holds roughly 100,000 completed tees—sufficient to produce your native muni for about three days, contemplating what number of vanish into the tough.

Picket Golf Tee Manufacturing: Portray and Ending

The ultimate transformation from bland picket sticks to colourful little troopers includes a paint celebration that may make Sherwin-Williams jealous.

Manufacturing employees load large totes of unfinished tees into specialised paint drums with the effectivity of caddies calculating yardage. Technicians launch gallons of coloured paint into this picket maelstrom. The rotation cycle continues for a big interval, guaranteeing full protection. As soon as totally coated, these colourful creations require ample drying time. A protecting enamel layer then enhances visuals and sturdiness, making a end glossier than tools catalog images. The finished tees transfer to packaging, prepared to fulfill their future: supporting golf balls for about 1.3 seconds earlier than being misplaced perpetually in grass, damaged in frustration, or pocketed by the man who by no means brings his personal tools. Such a wonderful however temporary existence—not not like your confidence after making one good swing on the vary proper earlier than heading to the primary tee.