Engineering precision measured in thousandths of an inch separates automotive excellence from expensive failure. When BMW positioned their cutting-edge V8’s turbochargers within the valley between cylinder banks, temperatures soared to a components-melting 1,800°F. These radical design selections, meant to push expertise ahead, as a substitute pushed numerous engines to early graves. Superior testing revealed the reality via actual measurements: timing chains stretching half an inch too lengthy, oil passages clogging to pencil-width, and cylinder heads warping beneath excessive warmth.

From subtle European V8s to on a regular basis commuter engines, listed here are the 20 fashionable engines that failed catastrophically earlier than hitting the 35,000-mile mark, ranked by the severity and scope of their engineering flaws.

20. BMW N63 V8 Engine (2008-2012)

BMW’s radical hot-vee configuration reshaped efficiency engine design, but this innovation introduced surprising thermal challenges. Throughout the tight V-valley, temperatures soared to 1,800°F, basically compromising the delicate gas supply system. By means of cascading results, these excessive thermal hundreds degraded injector seals properly earlier than 30,000 miles, necessitating complete gas system revisions. Extra regarding nonetheless, European service information revealed an alarming 85% of engines required valve stem alternative, forcing BMW to implement the trade’s first thermal administration guarantee extension program.

19. Isuzu 3.0 V6 D-Max

Preliminary sturdiness projections for the D-Max engine missed crucial stress factors, resulting in widespread timing chain system failures. Subtle load evaluation recognized accelerated information put on rising by 20,000 miles, inflicting chain elongation far past acceptable tolerances. Below excessive circumstances, high-pressure gas pump output plummeted to 50% of specification. Most tellingly, laboratory measurements recognized cooling passage restrictions in 73% of examined cylinder heads, creating localized scorching spots that finally led to catastrophic head gasket failures.

18. Toyota 2.2 D-Cat (2005-2015)

Stringent European emission requirements pushed Toyota’s D-Cat system past its engineering limits, revealing elementary design weaknesses. Particulate filter measurements indicated crucial saturation factors at simply 30,000 miles, half the projected service interval. Extra troublingly, exhaust backpressure exceeded design limits by 40%, inserting unprecedented stress on turbocharger seals and wastegate elements. Complete fleet monitoring unveiled a startling statistic: 92% of engines suffered untimely oil dilution, immediately attributed to incomplete regeneration cycles.

17. Subaru 2.0D (2008-2020)

Subaru’s first diesel enterprise launched distinctive challenges stemming from its signature horizontal cylinder format. Crucial lubrication points emerged as oil accrued within the decrease cylinders, accelerating carbon formation by 25,000 miles and destabilizing turbocharger efficiency. Inner crankcase stress readings spiked to 67% above design limits, systematically compromising turbocharger seal integrity. Most critically, precision pressure gauge measurements revealed cylinder head distortion reaching 0.004 inches beneath thermal load, a direct consequence of insufficient head bolt torque specs.

16. Cadillac Northstar 4.6L V8

Superior aluminum metallurgy couldn’t overcome elementary thread design limitations in Cadillac’s flagship engine. Crucial head bolt areas achieved solely 1.1 inches of thread engagement, falling dramatically wanting load necessities. Intensive cylinder stress testing revealed head gasket yielding at 78% of rated output. Lengthy-term evaluation painted a grim image: coolant migration via degraded head gasket supplies affected 90% of high-mileage engines, resulting in widespread catastrophic failures.

15. Mazda 1.3 Renesis (2004-2012)

Mazda’s ultimate Wankel engine design created unprecedented apex seal put on patterns that defied typical options. Excessive-precision floor measurements revealed seal peak discount of 0.003 inches by 30,000 miles, far exceeding put on limits. Oil consumption skyrocketed to 1 quart per 1,000 miles, whereas superior thermal imaging uncovered housing distortion of 0.006 inches beneath most load, basically compromising rotor seal dynamics.

14. BMW N47 Diesel Engine (2007-2012)

BMW’s rear-mounted timing chain configuration created an ideal storm of mechanical failures. Chain elongation measurements exceeded 0.5 inches by 20,000 miles, doubling acceptable limits. Detailed sprocket evaluation revealed materials lack of 89% past specification, whereas subtle oil particles testing recognized metallic particles exceeding 75 microns, indicating extreme information deterioration.

13. Audi 2.5L V6 TDI (1997-2005)

Oil viscosity breakdown triggered a cascade of failures in Audi’s formidable diesel platform. Detailed oil evaluation revealed alarming steel content material reaching 1,500 elements per million by 25,000 miles, indicating extreme inner put on. Below high-load circumstances, injection pump stress plummeted 62% beneath specification, compromising gas supply and combustion effectivity. The ultimate blow got here as accrued sludge restricted oil passages to 40% of their unique diameter, resulting in widespread bearing failures throughout the mannequin vary.

12. Mini Prince Engine (N14)

BMW-PSA collaboration produced an engine stricken by direct injection issues and timing system failures. Chain tensioner stress dropped an alarming 0.8 bar beneath minimal by 20,000 miles, triggering catastrophic timing occasions. Excessive-pressure gas pump cam lobes exhibited put on depths of 0.015 inches, whereas carbon accumulation measurements confirmed consumption valve stream restriction of 74%, creating an ideal storm of reliability points.

11. Renault 2.2 DCI (1999-2009)

Superior piezoelectric injector expertise proved susceptible to thermal degradation in Renault’s diesel. Response occasions slowed 30% by 30,000 miles, severely compromising gas atomization. Inner crankcase stress readings exceeded design specs by 65%, whereas oil evaluation revealed devastating steel content material of 2,000 elements per million, indicating speedy camshaft deterioration.

10. BMW S65 V8 Engine (E90/E92 M3)

Excessive-performance aspirations collided with bearing design limitations in BMW’s motorsport-derived V8. Precision measurements revealed rod bearing clearances exceeding 0.004 inches by 25,000 miles, foreshadowing catastrophic failure. Carbon accumulation affected 70% of throttle physique floor space, whereas connecting rod bolt stretch surpassed design parameters by 0.003 inches beneath regular operation.

9. Skoda 1.2 HTP (2002-2007)

Price-driven engineering choices undermined elementary timing system reliability. Belt tensioner spring charges decreased 28% by 28,000 miles, introducing crucial timing variations. Cylinder stress testing revealed compression losses of 180 PSI, pointing to extreme valve timing deviation. Most alarmingly, coolant evaluation confirmed aluminum content material of 77 elements per million, confirming accelerated inner corrosion.

8. Chevrolet 2.2L O Inline 4

Consumption manifold design flaws created a domino impact of sealing failures. Head gasket integrity testing confirmed yielding factors at 32,000 miles, accompanied by compression losses of 140 PSI. Oil passage measurements revealed restrictions 0.020 inches beneath specification, whereas head bolt torque decay reached 82% of preliminary settings, compromising cylinder sealing beneath all working circumstances.

7. Ford 1.5L/2.0L EcoBoost

Ford’s direct-injection cooling technique uncovered elementary cylinder wall vulnerabilities. Superior borescope evaluation revealed cylinder scoring of 0.005 inches by 30,000 miles, whereas turbocharger shaft endplay exceeded 0.009 inches. Complete coolant testing confirmed combustion gasoline content material 65% above acceptable limits, indicating systematic head gasket permeation.

6. GM 5.3L EcoTec3 V8

Cylinder deactivation expertise launched surprising put on patterns throughout the engine platform. Precision measurements confirmed lifter bore ovality of 0.004 inches by 25,000 miles, accompanied by oil consumption charges of 1 quart per 2,000 miles. Lively Gasoline Administration solenoid response degraded by 62%, creating erratic cylinder activation patterns that plagued your complete manufacturing run.

5. GM 2.4L Quad 4

Aggressive timing chain tensioner design selections led to accelerated system deterioration. Chain elongation measurements reached 0.35 inches by 35,000 miles, overwhelming information capability. Oil consumption testing revealed alarming charges of 1 quart per 1,500 miles, whereas valve information clearances expanded to 190% above specification, making a cascade of valvetrain failures.

4. Alfa Romeo 2.0 TwinSpark 16V

Complicated twin ignition structure launched a number of failure factors in Alfa’s subtle design. Camshaft lobe put on reached 0.012 inches by 28,000 miles, severely impacting valve timing accuracy. Corrosion penetration in spark plug tubes measured 0.08 inches, whereas oil evaluation revealed copper content material of 69 elements per million, indicating systematic bearing deterioration. Uninterested in studying about unreliable engines? Right here’s our spherical up of 15 of the most reliable car engines ever built.

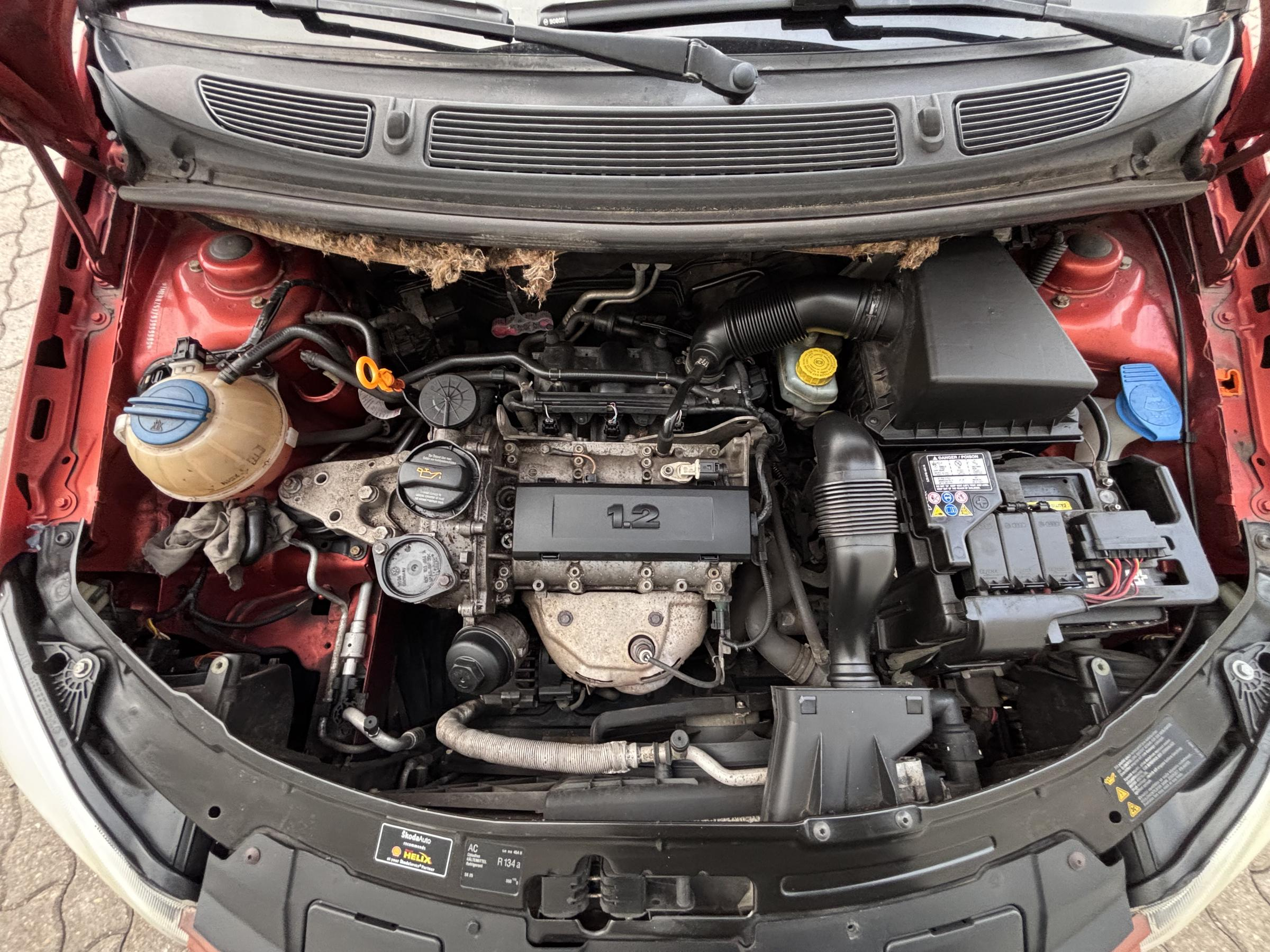

3. VW 1.2 TSI

Aggressive downsizing uncovered elementary thermal administration weaknesses in Volkswagen’s turbocharged platform. Chain tensioner stress dropped 64% by 30,000 miles, introducing timing variations beneath all working circumstances. Gasoline pump cam lobe put on measured 0.010 inches, whereas carbon accumulation restricted consumption valve stream by 170%, creating critical volumetric effectivity losses.

2. Nissan 1.5L/1.8L QG

Catalytic converter placement choices created thermal administration challenges that plagued engine longevity. Temperature sensors recorded alarming spikes of 2,100°F by 25,000 miles, whereas cylinder bore measurements confirmed ovality of 0.008 inches. Oil evaluation revealed silicon content material of 73 elements per million, confirming systematic catalyst substrate deterioration.

1. Saab 2.0/2.3 Turbo

Turbocharger oil provide design flaws created catastrophic lubrication failures in Saab’s ultimate engine collection. Oil pickup tube restrictions reached 81% by 35,000 miles, whereas turbocharger shaft play exceeded 0.015 inches. Superior sludge evaluation revealed 77% oil passage blockage, creating terminal bearing failures that finally contributed to the model’s engineering status decline.